Choosing the right tyres for agricultural machinery is critical to farm productivity, cost savings, and soil health. The two most common types of tyres used on farm equipment are radial and bias ply tyres.

While both have their unique advantages, understanding the key differences between them can help farmers make informed decisions that best suit their specific machinery, tasks, and field conditions.

In this article, we’ll take an in-depth look at radial and bias ply tyres, comparing their construction, performance, and best-use scenarios to help you determine what’s best for your agricultural operations.

What Are Radial Tyres?

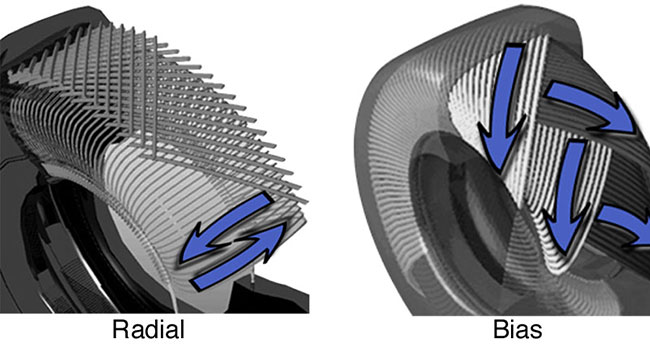

Radial tyres have a more modern construction compared to bias ply tyres. The main feature of radial tyres is their flexible sidewall and rigid tread, which are the result of their distinct construction. Radial tyres are made with layers of steel belts running perpendicular (at a 90-degree angle) to the tread, and radial plies extending across the tread. This design allows for better contact with the ground, less heat build-up, and improved flexibility.

Advantages of Radial Tyres:

- Better Traction: The flexible sidewalls and large footprint allow radial tyres to grip the ground more effectively, providing superior traction in muddy or wet field conditions.

- Reduced Soil Compaction: Radial tyres distribute the machinery’s weight more evenly across the surface, which reduces soil compaction. This is essential for preserving soil structure and optimizing crop yields.

- Longer Lifespan: Due to the even distribution of pressure across the tread, radial tyres tend to last longer than bias ply tyres. The reduced wear on the tread translates to cost savings over time.

- Fuel Efficiency: Radial tyres experience less rolling resistance, which means your machinery will consume less fuel during operation. This is particularly beneficial for large-scale farming operations where fuel costs are a significant expense.

- Smoother Ride: The flexible sidewalls of radial tyres absorb bumps and shocks more effectively, providing a smoother ride for operators and reducing machinery wear and tear.

Disadvantages of Radial Tyres:

- Higher Initial Cost: Radial tyres are more expensive to purchase upfront compared to bias ply tyres. However, their longer lifespan and fuel efficiency often make them more cost-effective in the long run.

- Heavier: Radial tyres tend to be heavier, which can be a drawback for smaller or older equipment that may not be designed to handle the extra weight.

- More Susceptible to Sidewall Damage: The flexible sidewalls that provide many of the benefits of radial tyres are also more vulnerable to damage from sharp objects or rough terrain.

What Are Bias Ply Tyres?

Bias ply tyres, also known as cross-ply tyres, have been in use for decades and are constructed with multiple layers of fabric plies placed diagonally to the tread. The plies overlap each other in a crisscross pattern, giving the tyre its name. This construction results in a more rigid sidewall, offering durability but at the cost of flexibility and traction.

Advantages of Bias Ply Tyres:

- Durability: Bias ply tyres are robust and resistant to cuts and punctures due to their thicker sidewalls. They can endure rough, uneven terrain, making them ideal for use in rocky or hilly environments.

- Lower Initial Cost: One of the main attractions of bias ply tyres is their affordability. They are generally cheaper than radial tyres, which can be a deciding factor for farmers on a tight budget.

- Strong Sidewalls: The rigid sidewalls provide better protection against sidewall damage, which can be an advantage when operating in harsh conditions like forests, brush, or stony ground.

- Better Stability at Low Speeds: Bias ply tyres offer good stability at low speeds, which can be useful for operations such as towing or working on rugged terrain where speed is not a priority.

Disadvantages of Bias Ply Tyres:

- Less Traction: Due to the rigid sidewalls and smaller footprint, bias ply tyres do not offer the same level of traction as radial tyres, particularly in soft or wet ground conditions.

- Increased Soil Compaction: The design of bias ply tyres leads to a smaller ground contact area, which concentrates the weight of the machinery over a smaller space, resulting in higher soil compaction.

- Shorter Lifespan: The rigid construction of bias ply tyres causes the tread to wear more quickly and unevenly, especially if the machinery is used on hard surfaces like roads or compacted soil.

- Higher Fuel Consumption: The stiffer construction of bias ply tyres leads to greater rolling resistance, which increases fuel consumption compared to radial tyres.

Key Differences Between Radial and Bias Ply Tyres

| Feature | Radial Tyres | Bias Ply Tyres |

|---|---|---|

| Construction | Steel belts and radial plies at 90° angle | Crisscross layers of fabric plies |

| Traction | Superior traction, especially in wet fields | Less traction, particularly in soft soil |

| Soil Compaction | Reduced soil compaction | Increased soil compaction |

| Ride Comfort | Smoother ride due to flexible sidewalls | Stiffer, rougher ride |

| Durability | More susceptible to sidewall damage | More resistant to sidewall damage |

| Fuel Efficiency | Better fuel economy due to lower rolling resistance | Higher fuel consumption |

| Lifespan | Longer lifespan due to even tread wear | Shorter lifespan, prone to uneven wear |

| Cost | Higher initial cost | More affordable upfront |

Which Tyre is Best for Your Agricultural Machinery?

Choosing between radial and bias ply tyres depends largely on your farming needs, terrain, and budget. Here’s a breakdown of which tyre type may work best for different conditions:

- For large-scale, soft-soil farming: Radial tyres are the clear winner. Their ability to reduce soil compaction and improve traction makes them ideal for farms with large, heavy machinery working on soft or wet soil. Their longer lifespan and fuel efficiency also make them more economical in the long run, despite the higher initial cost.

- For rough, rocky terrain: If your machinery is frequently used on rocky, uneven, or forested land, bias ply tyres may be the better option due to their durability and strong sidewalls. They can withstand harsher conditions and are less susceptible to sidewall damage from sharp objects.

- For budget-conscious farmers: Bias ply tyres are a more affordable choice for those who need durable tyres for rugged conditions but can’t invest in the higher upfront cost of radial tyres. However, it’s important to consider the trade-off in terms of fuel efficiency and lifespan.

- For specialized tasks: If your machinery is used primarily for high-speed road travel between fields, radial tyres offer better ride comfort and fuel efficiency. On the other hand, bias ply tyres may perform better in low-speed tasks like towing or ploughing in rough terrain.

Conclusion

Both radial and bias ply tyres have their place in agriculture, with each offering distinct benefits depending on the application.

Radial tyres shine in situations where traction, soil preservation, and long-term cost efficiency are important, while bias ply tyres offer a rugged, durable solution for harsh terrain and budget-conscious operations.

By understanding the key differences and evaluating your specific farming needs, you can select the best tyre type to enhance the performance of your agricultural machinery.

Also Read

Top 9 tyre maintenance tips for long-lasting farm machinery performance

Tires vs. Tracks: Which is best for your farm machinery?